|

|

|

|

|

What Can I do for you today? Imagine the following scenario: You are working on several critically important projects that are all running behind. A timeline that looked relaxed and realistic a week ago is now looking impossible. Eventually, checkpoint after checkpoint has passed and it has become clear that the process that you have used to separate the merely important from the absolutely critical has failed. One project in particular appears to be failing, and yet everything in your life is getting in the way of getting it finished. In the classic manner ... for want of a nail a shoe was lost ... this project's problems are now threatening the others. Question: How can you change the direction and save the day? Answer: Have me finish one of the projects for you. Multiply your span of control with a temporary infusion of senior-level talent. I will apply a level of skill, insight and perseverance comparable to your own. Just send me the project files and I will wrap it up for you. |

|

Facilities Offered

|

Core Services Offered

|

Relevant Skills include:

|

|

PRICING: My basic premise is simple - everyone's time is precious and there is not nearly enough of it to go around. Therefore, my time is worth EXACTLY the same as yours - no more, no less. So it comes out to your advantage to pay me to do those things that I do faster or better than you, or even things that I only do about as fast as you do them, but that you can't find time to do AND simultaneously do the things that you do faster than I can. Pretty simple, no? |

||

|

RECENT AND ONGOING PROJECTS: In January 2007 I got a letter from a guy at RISD ... He explained how he'd found me, and what skills he was looking for, and then he asked a very simple question: "Do you think you have time for one more big project?" And when I looked at what he wanted to do, I knew the answer was "YES!" He wanted to manufacture small energy-efficient affordable houses that are built in a factory, but ship knocked down and assemble onsite with a small local crew. So, I dove into researching the options, and found that there were lots of people on this path already, including knock-down shipping masters IKEA. My RISD friend had found me cuz of the work I had done years ago, developing a rapid, low-cost tooling system for complex shapes: molded boats, horn-loaded loudspeakers, a graphite composite piano, and many other big, complicated molded products, and the text-book I had written for Woodnet on scaling up a series-production system (artisan woodworking) into a factory model. But since those days I have become more and more suspicious of polymer chemistry and the biological activity of many of the chemicals that we used to use. Quite simply, I wanted to build houses that were genuinely affordable - both up front and long term - for single moms, and I did not want to put single moms in houses made from most of those materials. The questions appeared to be simple "What to use?" and "How to use it?" So I dove into a full-scale research project looking for alternate, more appropriate technologies, looking for healthier materials (better for the people who would be working with the materials in the factory and better for the people living in the houses) and lower embodied energy (better for the planet) This research project has turned out to be something of a prairie dog nest - it has gone on and on and on, emerging from one rabbit hole only to dive down another. About 35 years ago I ran into a truism that has gradually become a breskinism "Genetic engineering should not be about stem-cell research aimed at preventing aging in baby boomers. If we are doing it at all we should be figuring out how to grow 20' diameter pumpkins with your choice of floorplans." So I catalogued dozens of potential materials and tried to figure ways to use them efficiently in a factory situation, where house parts and subassemblies could be created quickly and cheaply, using the production methods that I wrote about in the design engineering textbook I put together for Woodnet in the mid-1990's. I visualized a computerized drag and drop front end that generates a floorplan that gets run against a set of "rules" and suggests revisons repeatedly until the plan finally passes a variety of code and other requirements and then creates plans for the plumbing and the wiring and the ducting, does the structural engineering and ultimately drives the mold-configuring system. All I needed, I thought, was a clear sense of what I was going to use as the building materials and a fundamental good design for connecting the panels - foundation to floor, floor to wall, wall to ceiling, etc. and then I could start designing the panel fabrication system file the patent applications, finish emptying and reconfiguring my shop, and start setting up production tools. Hah!!! This is the biggest problem I have EVER taken on, and possibly the bigget problem I have ever seen anyone - or even a team - tackle.

|

||

|

Winter 2009 Major shop clearing to reconfigure for production. All molds, construction materials and the boneyard containing the remnants of prior projects were removed from site. | |

| Summer 2009 first skylight test unit based on triple-layer or quad-layer glazing got installed. Designed using low cost locally available materials, using the software packages THERM and WINDOW. | ||

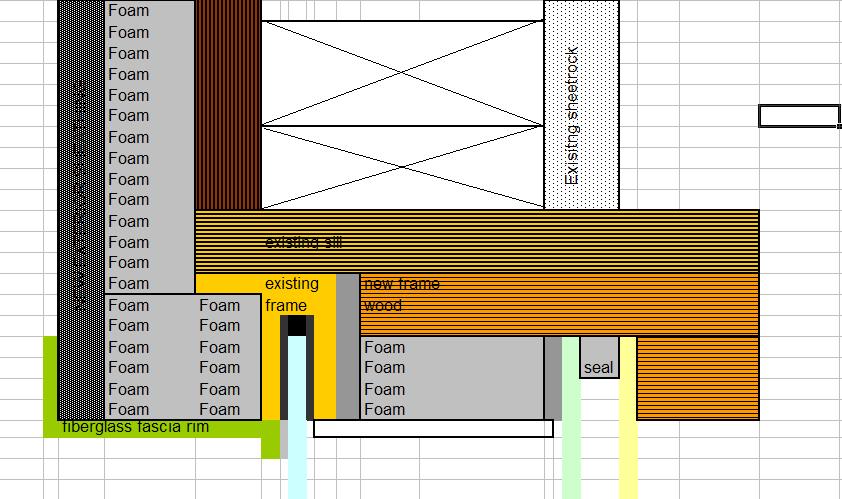

| Early Summer 2009 JBD/E

submitted permit application drawings for an in-city energy efficiency

retrofit based on custom low-cost site-built windows, computational fluid

dynamics models. In response to the needs of a customer's house-remodel project, that had to meet the City's implementation of our state's energy code, I started designed some very cheap-to-build energy-efficient window upgrades, using existing sash and adding readily available low cost materials to improve performance, using the LBNL software packages THERM and WINDOW. Easiest to visualize these windows as indoor-mounted thermopane storm-windows.

| |

|

In Feb 2009, I attended a workshop with Katrin from PassiveHouse Institute US and one of the most important messages I came away with was that everyone building to this standard needed to buy HRV systems and

high-performance windows, and that either or both made more sense (as products) than houses. Because there

is little or no competiton for market share: everyone building to the PassivHaus standard was going to need to buy windows and that at this point in history, there were NONE being made in the USA with performance that met the Passivhaus requirement.

Then she pointed out that providing windows for the 1500+ Passivhaus projects that had been in Europe had created a thriving economy for dozens of artisan shops making windows and doors. So I started designing energy efficient windows upgrades, using low cost materials, using the software packages THERM and WINDOW.

|

|

| Spring 2009 A consortium of JBD/E and 2 local architects submitted a proposal/bid to EcoVillage in response to their RFP for affordable house involving SIP construction and PassiveHouse technology. | ||

| Fall 2008 major shop reconfiguration effort in preparation for prototyping and setting up the affordable house production environment. Several steps proceeded in parallel. Unfinished projects were declared dead and if they could not be relocated, were destructively removed to free space in shop. A 30' wooden sailboat was reduced to kindling. (Image) |

|

In 2007 I did a fascinating hardware installation / configuration project for a local business that involved design and construction of a large vacuum-clamped cutting table for a high-speed computer controlled cutting machine. The cutter manufacturer required that the table be (and remain) level and flat within about ± ½ mm across a surface that is nearly 6' wide and 36' long. I assure you, this is NOT the standard specification that high-end builders work to in Port Townsend. Not when it's sitting on a wooden floor on the second floor of an old building that was built on fill. Then came debugging the machine and getting the computer systems bulletproof. In 2008 I made several refinements to the system's operation and this winter I will install the fixed laser that will simplify table re-leveling as building continues to settle in the future. Table was designed to be easily dismantled, moved and reassembled, if necessary |

||

|

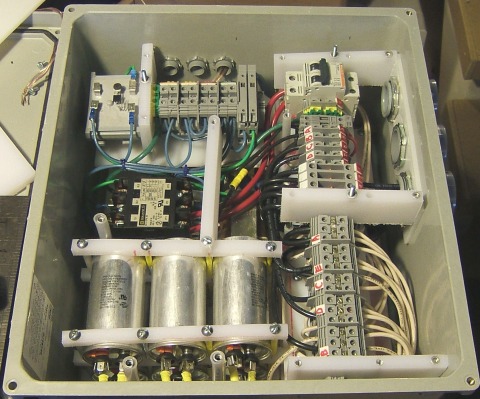

In late 2006 into 2007 I started working on a project for a local startup company 123phase, Inc. for Otto JA Smith on his patented three-phase motor enablers, microprocessor controlled devices that allow three phase motors to run better, with lower starting current on single phase power than they do on three phase power. JBD/E did the hardware design that integrates the components into a pair of small, manufacturable devices. These enablers allow electric motor driven pumps running on renewable energy to replace diesel powered pumps in many areas of the western US and elsewhere - anywhere three phase power is not available or not reliable This substitution will reduce power consumption and reduce air pollution that has been an accepted part of crop irrigation since WWII. Next step: set up a manufacturing system/production line. |

|

| Spring - summer 2004 major

facility cleanup - precipitated by inquiries from several parties wanting to

lease or purchase the shop facility and the recognition that prior to any

transfer or new business begfinning operation on the site, all potential

liability issues stemming from prior uses needed to be addressed.

Cleanup involved removal of many pails of polyester and epoxy resins, and reactive isofoam components to the County moderate waste facility and recycling of dozens of water filled steel resin drums. These were steel resin and acetone drums that had been positioned around the site, filled with water for use as fire suppression in the event of wildfire. . |

||

| Drums had been resin-sealed internally, but were now rusting from the outside and LOOKED like a serious toxic waste problem and were dealt with as though they were in fact full of toxics. Barrels were catalogued. Contents were removed and boiled down to create a dry solid. Resin coating was mechanically removed, then both ends were removed from each barrel, and then barels were flattened and then folded in half to densify before transport to recycling | ||

| Recent Big Picture Consulting | ||

| After the EDC unraveled and the Affordable Housing Task Force got co-opted, I swore to my friends that I would NOT go to meetings anymore But last summer I started to get

quite concerned about what was happening at our local Food Coop, and the growing gulf between the warm fuzzy feel of the Coop's advertized policies that were informing the members and the complex legalistic maze of actual policies that were informing the management

decisions at the store. So I got involved with the newly elected Board and

we set up a committee to revise and harmonize and integrate the two disconnected sets of

policies. So I built us a website that is pretty darned interesting,

if you have any interest at all in the politics and economics of the organic

food distribution business.

|

||

| In February of 2006 I was hired to develop a regional planning document,

called the Community Economic Development Strategy. Almost immediately, the NGO that hired me: The Economic Development Council of Jefferson County, was hijacked.

A useful metaphor is that the hijackers got into the cockpit, convinced the pilot to fly into the enemy's territory and land there.

But the pilot bailed out and parachuted to safety (landing, ironically, in the

Green Zone in Iraq to do economic planning there - really!). But by that time the

plane was

seriously off-course and I was hired to try to get the plane (which was in

danger of running out of fuel with a lot of important stuff on board) onto a safe runway with the landing

gear down, or to get the ground crew ready with foam deployed. Well, w got the plane down in more-or-less friendly territory and much to my

personal amazement the passengers decided to take off again, immedaitely. Which is the

"Just So Stories" version of how I came to be at or near the controls

(Interim Director) of a rather amazing 501(c)(4) social welfare organization that seems to have enormous potential to improve the conditions of almost everyone I know.

|

||

| WEBSTUFF The latest web-related thing I have tried was something I did for myself - an experiment in positioning some pages on the Google search engine. I built an online store that I called Divest-Store. I built it from the ground up in simple hand-coded html hoping to find an easy way to get rid of my excessive collection of accumulated treasure and in the course of building it and watching traffic closely over a week or so, I figured out how Google worked, and how to get pages immediately to the top of the Google rankings. As of 12/31/03 most of the items listed on my pages were getting higher rankings than their manufacturers' own sites. These two pages have proven to be the most popular, and at the peak of their popularity, before the majority of the really cool stuff was gone, they were each racking up well over 30,000 hits a month. http://www.breskin.com/forsale/speakers.html http://www.breskin.com/forsale/musictoys.html This demonstration of my ability to develop a simple strategy to generate web-traffic does NOT mean that I have figured out how to automate the far more important task of extracting money from the sites' visitors, nor overcome the nearly insurmountable problems involved in shipping some of my stuff. Like my house and shop. In fact, figuring out how it works - which was triggered by actually paying attention to what was right under my nose, literally right in front of me on the screen - was followed by about a week of concerted experiments. Which has led to a fascinating dilemma: an ethical dilemma. Obviously, this has value to other people, people with "commercial websites." I know this cuz people want me to do it for their sites, naturally. But how can I update their sites to rank high w/o demonstrating to their imbecile webmasters (who have taken their money promising "search engine optimization or search engine friendly" but who clearly still believe everything the read on the web, including metatags, the fundamental generosity of Google and the route that will be taken by Santa Claus ...) exactly how it works? It is not supposed to be a problem, but somehow it irks me that these people will then proceed to charge the rest of their customers to implement solutions they would otherwise have remained too lazy to discover for themselves. Tell me it

should not bother me but it does. Anyway, I am still looking for interesting projects, projects that are really

worth doing.

OTHER INTERESTING STUFFFFF By far the most interesting project that I've done in the past decade, beside

figuring out how to recapture the heat typically lost in residential dwellings, was the development of a smart building code for the Oregon Country Fair. The Fair is a temporary city that runs for one month a year - and when it is running, it is the sixth largest city in the State of Oregon. Think Disneyland, to get a sense of scale. The Fair is a corporation that owns a lot of land but most of the land is located in a flood-plain, and much of the site is inundated regularly. To meet the requirements of State and local jurisdictions, the Fair developed and adopted a Land Use Management Plan, and to tie this plan to the built environment I developed a "smart building code" in close collaboration with the Fair's Board and Construction Supervisor,

a building code that uses the Fair's existing Red-Tag system to transition a huge collection of picturesque but non-conforming structures into code-compliant structures.

My history with the web goes back to the days when there was no graphical user interface, and the web was not yet commercial, but in the beginning I usually did the system design and had others do the coding. in 1999 I decided to get fluent in the world of Browser-independant code. For the past 4 or 5 years I have assumed that client-side apps that shared data but ran either peer-to-peer or client-server architectures (and client-side applications) were the future. Lately, I have begun to wonder how much can be accomplished with pure HTML. Some of my experiments are online. Right now (2005) I am now returning to a client-server model and delving into php. |

||

|

For Example:

The Salmon Site was developed for WSU-CE in late 1998 - early 1999 as a test-bed for getting three CE campuses to adopt a common data organization metaphor into which county-specific local content related to salmon and salmon habitat could be loaded. The idea behind this was that the recognition that state's land-grant universities, through their Cooperative Extension Offices, are well positioned to provide information that will help communities improve the effectiveness of their efforts to help endangered fish. The version I have online on their site was intended to demonstrate HOW some simple HTML tools might be used to organize data in a quasi-geographic hierarchical system with a pure HTML interface. The most interesting ideas I have implemented on this site are the purely graphical interface to a collection of aerial photos of a recent flood in the Chimacum Valley. Another related idea is the nearly self-explanatory user interface that uses the legend icons to filter the clutter from . a map-based interface. A similar strategy was used to mate the keys with the maps on the old DOE Coastal Zone Atlas also on the Salmon Site. |

||

|

Other Innovative Solutions:

I have a developed some simple tricks for getting large amounts of complex data onto the web. The best of these can be seen at customer's sites, such as:

the pin-map I developed for D & A Instruments Company. Unfortunately the page has been changed recently and is not as effective as it was. The trick provided an effective way to "graphically" normalize data, using the ratio of calculated volume of "sphere" that is observed by the viewer to the actual area (pixel-count) of the sphere's on-screen representation to provide a scale-compression. Current version of the page does not use the spheres and hence, loses the compression factor. Another page I developed for this client implements a product selection matrix with clickable GIFs. |

||

|

Less Immediate Projects

During the winter of 1994-1995 I wrote a book about what I had learned in the past two careers, putting it into a text-book intended to teach Design Engineering to Secondary Wood Products manufacturers in a community college course. The book defined the information management requirements of a scalable organizational model, and identified many of the obstacles to success in a small-to-medium scale manufacturing operation. More importantly, it offered paths around many of them. The model provided in this book was used to scale Foresight Science & Technology into a highly effective team-based operation - basically a market research factory. Sponsored Research

A reasonably complete listing of research reports and publications (through April 1998) accompanies the resume that can be found elsewhere on this website. Terms and Conditions:It is understood that the customer is entitled to want to know how much it will cost, how long it will take and how good it will be. It is also understood that no-one can ever know all three of these AND have the cost be low, AND the time be soon AND the quality be excellent. This creates a fundamental tension that is best resolved through clear product deliverable specifications and accurately defined project milestones and deadlines. It is useful to understand that EnviroSearch is not necessarily your best choice for product development if fast and cheap are more important than good or lasting, or if the characteristics of the desired final product are not well understood. Unless you are willing to revisit the basic assumptions and involve me in the design process as well.

|

||

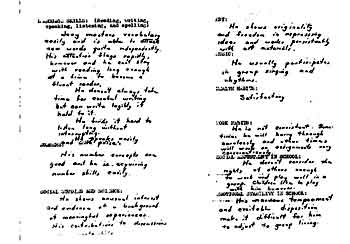

click image for a readable full screen scan - a 40 KB jpg |

JOE BRESKIN'S FIRST GRADE REPORT CARD Here is what this says, or at least this is what I see in it that I still find highly predictive: it cuts right to the fundamental problem of my life: that my talents and my traits are caught in a battle to the death and that it will be difficult to change the path I am on. There is already evidence of unusual talent: "he masters vocabulary easily" "he shows unusual interest and a background of meaningful experiences" and even the ability to process these interests and meaningful experiences into language: "his contributions to discussions are worthwhile" but this is contrasted with my destructive behavior traits "he interrupts others" "he doesn't consider the rights of others well enough to work and play well in a group" and so the summary - which might best be listed in a separate a category labeled "Charisma" concludes (to paraphrase only slightly) that in spite of his arrogant behavior and destructive attitude other children like to play with him anyway. |

|

|

ACTIVITIES OTHER THAN WORK

|

EDUCATION 1965 - 1973: University of Washington, Seattle Extensive course-work in fields of:

|

|